SOFTWARE

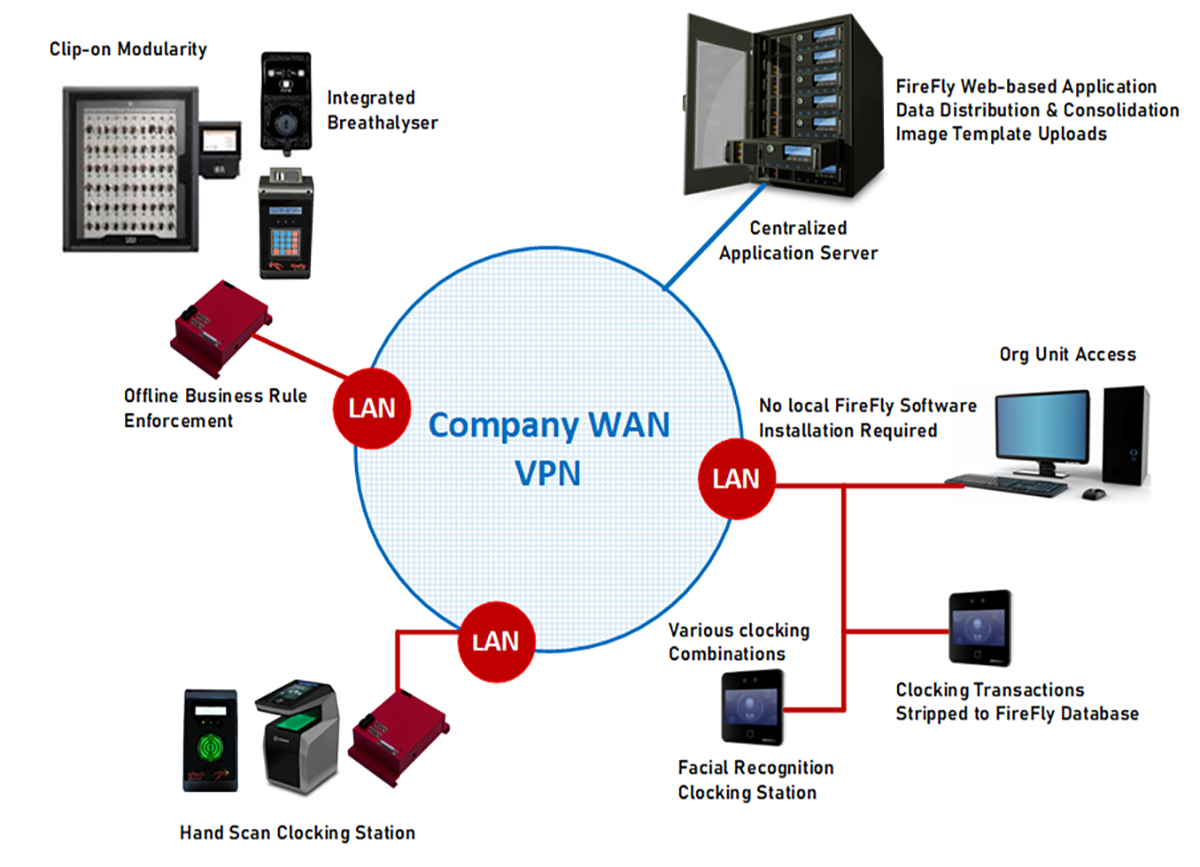

The FireFly solution is a proudly South African product range developed as a

cost-effective modular,

robust solution catering for the extreme and ever-changing environment that our technology driven,

functionality rich products operate within.

The FireFly software solution is a seamless web-based platform, integrating multiple system disciplines and architecture with the goal of providing an

always available,

paperless and error free environment that enforces all customer

business rule requirements.

The FireFly software solution includes one of the most

feature-rich workforce management systems available in the Mining and Heavy industrial business sectors respectively.

Reliability, second to none, and customer driven

customisation are key components for

future-proofing customer-centric business partnerships.

FireFly Solution Benefits:

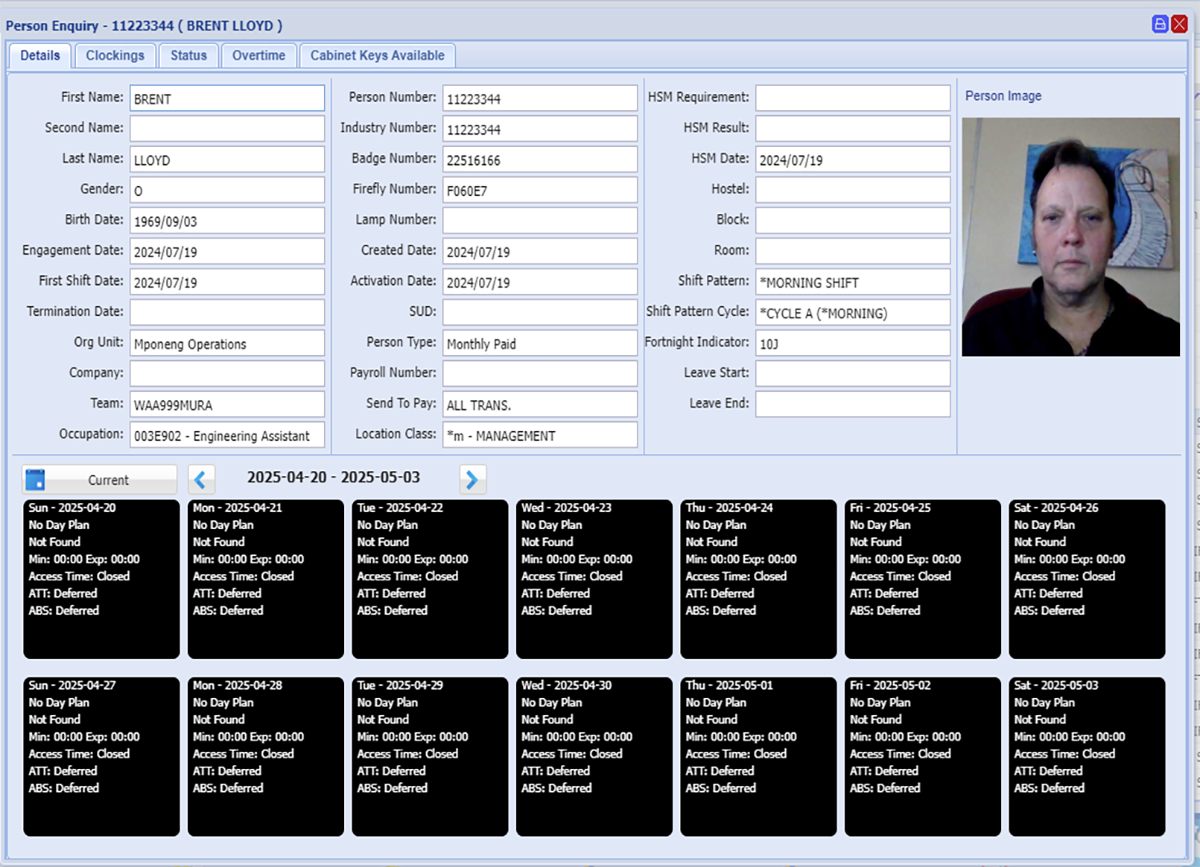

- Customer Specific Business Rule Enforcement

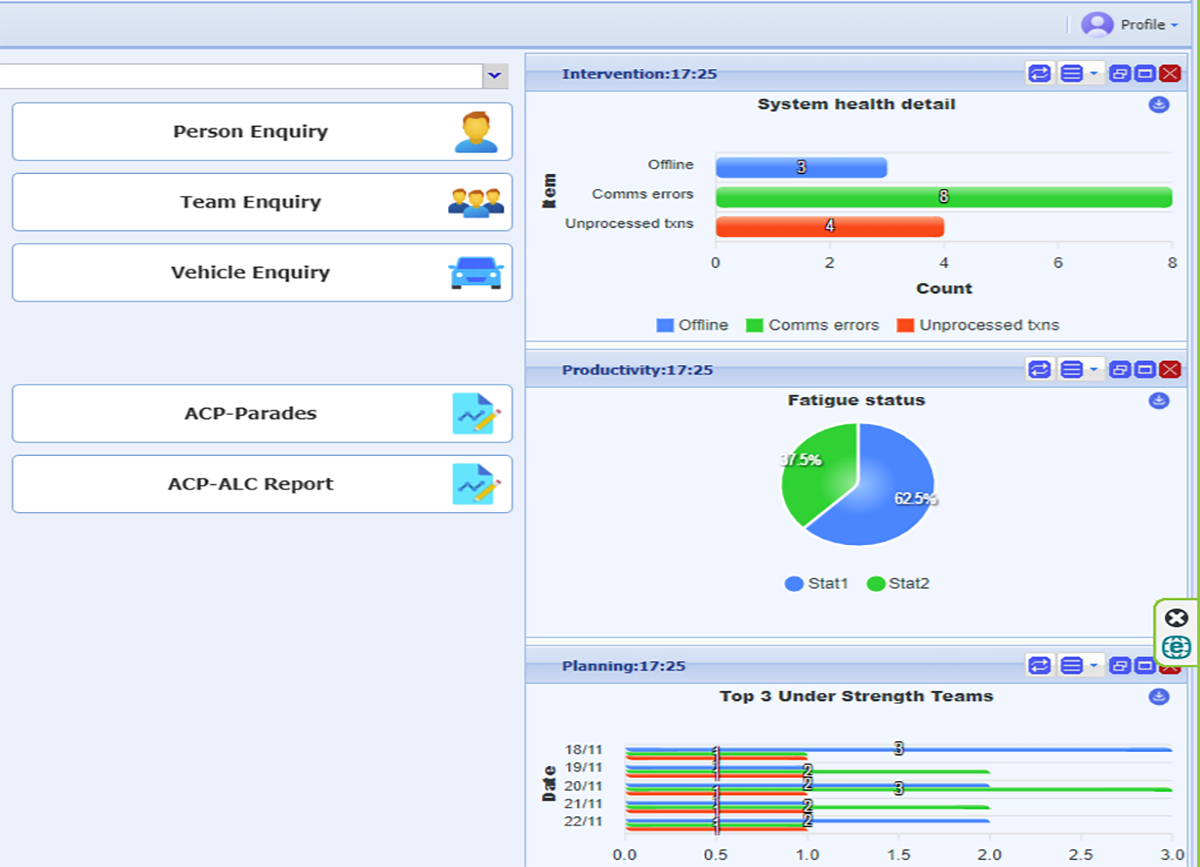

- Improved Operational Efficiency

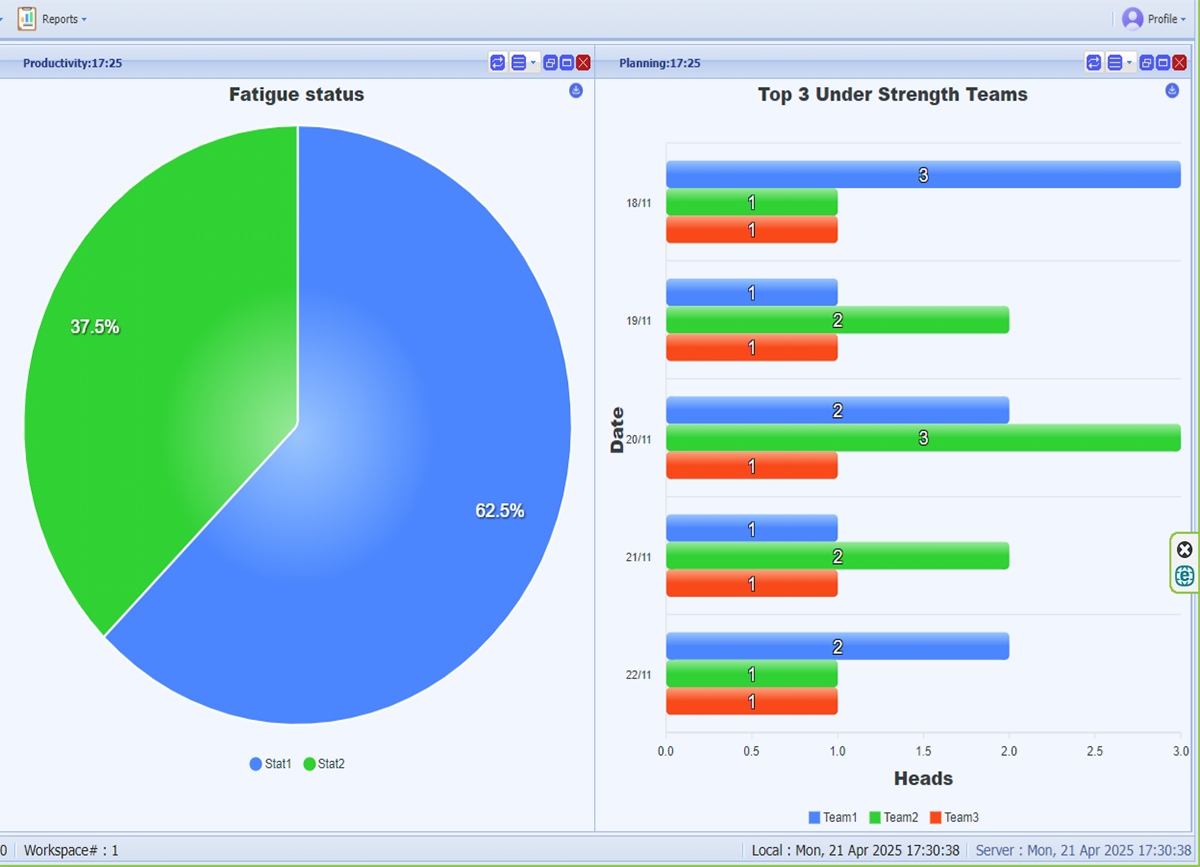

- Increased Productivity

- Reduced Operational Costs

- Enhanced Decision-Making & Visibility

- Health and Safety Compliance

- Improved Employee Morale